| This fanfiction article, M28 rifle, was written by StoneGhost. Please do not edit this fiction without the writer's permission. |

| This article is part of Swarmverse, an inactive expanded universe made defunct by newly created canon material. |

| |||||||||||||||||||||||||||||||||

| [Source] | |||||||||||||||||||||||||||||||||

The M28 assault rifle was a family of bullpup, air-cooled, gas-operated, selective fire assault rifles in use with the United Nations Space Command during the Swarm War. The M28 was chambered for the 7.62x51mm NATO full power rifle cartridge, which gave it significant stopping power and range whilst being suitable for controlled, accurate automatic fire. Design of the M28 was initiated in 2620, following the 2619 Strategic Defence Review, which called for military escalation and rearmament as a result of increasing galactic tensions. Production of the weapon began in 2625, three years into the Galactic War, and the M28 gradually replaced the MA6 assault rifle as the UNSC's service rifle over the next five years.

The M28 was designed from the start with modularity in mind, and featured three baseline variants with interchangeable recievers, barrels and gas systems. These variants took the form of the base rifle, acommodating a 22 inch barrel, as well as a designated marksman rifle with a 26-inch barrel and a shortened carbine with a 16.5-inch barrel. Parts and ammunition commonality between the variants was a major consideration in replacing a number of separate weapons systems with a single rifle family, as was the significant weight savings the M28 made over its predecessor, the MA6.

History[]

The M28 assault rifle was designed in the early 2620s to replace the UNSC's previous generation of 7.62mm calibre weapons, the MA6 assault rifle, the M392 designated marksman rifle, and the M40 carbine. As a result of the 2617 Strategic Defence Review, the UNSC began a renewed program of military research, development and expansion in the wake of heightened galactic tensions from 2616 onwards; this effectively counteracted and exceeded the reductions in military size and budget detailed in the earlier 2567 Strategic Defence Review. Development of the M28 was remarkably rapid, and by 2625 the first weapons were being manufactured. Against the backdrop of the now-raging Galactic War, the M28 began replacing the MA6, M40 and M392 in service, a process that was complete by 2630. The Galactic War was concluded in 2633 with no clear victor; only the emergence of the new threat of the Swarm ended the war, beginning the Swarm War which would plunge the galaxy into conflict until 2678. The M28 served throughout this war, seeing extensive conflict against the Swarm wherever the UNSC encountered them.

Usage[]

Design[]

The M28, like many UNSC weapons, featured a bullpup layout, which positioned the action and the magazine behind the trigger. This increased barrel length compared to the overall weapon length, which increased muzzle velocity and therefore range and accuracy. The majority of the weapon's upper receiver was taken up by an integral monolithic attachment rail, which was used for the attachment of aiming devices, such as iron, reflex or telescopic sights. The weapon's sides, stock and the ergonomically-designed pistol grip were constructed from lightweight FRP (fibre-reinforced polymer) made of a polymer matrix reinforced with fibres (a carbon fibre/kevlar mix), which was lightweight yet strong and resistant polymer. The upper receiver, rails and magazine assembly were constructed from high grade steel, while the trigger assembly, bolt and bolt carrier were precision-machined titanium alloy. The rifle was modular, meaning that it was assembled in interchangeable sections that were easy to separate and replace.

Due to its selective fire capability, several measures were taken to improve handling and reduce recoil. The weapon featured a venting system that recovered part of the gases generated by the round, and pushed it back in a space located behind the bolt during the cycle. This caused the bolt to 'bounce' on a sort of 'gas cushion' that acted as a buffer, dramatically reducing the weapon's recoil and reducing wear on the bolt face. It also featured energy absorption mechanisms in the buttstock, absorbing energy and reducing felt recoil. The carbine's bullpup nature meant that it was somewhat back-heavy; however, this was counteracted by long barrels in the case of the standard and DMR variants, and an integral vertical foregrip in the carbine variant, all of which reduced muzzle climb. The barrel end featured a large, birdcage-type flash suppressor which reduced the barrel's muzzle flash and directed it away from the shooter's vision; as a secondary function this vented excess gas in a way counteractive to the weapon's muzzle climb and backwards recoil. The barrel itself featured counterclockwise threading and was able to accept additions such as different flash hiders, muzzle brakes or suppressors once the standard flash hider was removed.

The M28's lower receiver featured another attachment rail or, in the case of the carbine variant, sacrificed this for an integral, non-detachable vertical foregrip. This grip assisted the weapon's controllability in automatic fire by managing muzzle climb, and assisted the user in balancing the back-heavy weapon. It also served the function of lessening the chances of the user putting his hands in front of the the short carbine while it was in operation. The M28 also mounted a removable rail on either side of the carbine, which could accommodate various aiming aids and other devices, commonly 'smart linked' sights, flashlights or laser aiming modules, or could be fitted with rail covers. The M28's cocking handle was located directly above the fire mode selector, and was accessible through both sides of the weapon. The bolt remained stationary locked forward while the weapon was in operation, and slid back upon the last round being fired, and was locked back by a bolt catch. When a new magazine was inserted, the user disengaged the external bolt catch, releasing the bolt forward, chambering the first round and moving the striker to the ready position. As the weapon was designed to utilise caseless ammunition, it did not feature a mechanism of ejecting spent casings; however, there was an ejection port located directly above the magazine and chamber. This was utilised to inspect the chamber or clear it of any jammed rounds, and opened by sliding back in the same manner as the bolt. The port would only open once the bolt handle was pulled back, not whilst the weapon was in operation; it would only open either when the operator manually pulled back the bolt or when the bolt locked back on firing the last round. The design of the port was altered after tests showed this opening would vent propellant gases and heat into the user's face after firing.

The M28 featured a fluted barrel constructed from a titanium/ceramic metal matrix composite, lined with a super heat and friction-resistant silicon carbide ceramic matrix composite. This gave the barrel an effective life of 30,000 rounds before it needed replacing, as well as reducing its weight over steel barrels by 56%, and largely eliminating overheating weapons even after sustained fire. Behind the ergonomically designed grip and trigger assembly was the magazine well, which featured flared inside edges to assist with rapid reloading. The weapon accepted as standard the M9 Magazine, which held 30 caseless rounds in two block columns, giving it magazine compatibility with the MA6 assault rifle it replaced. The magazine release was located just above the magazine port on both sides of the weapon.

Ammunition[]

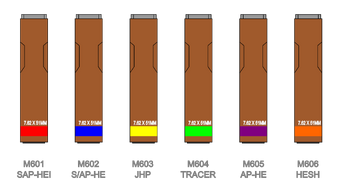

The various forms of 7.62x51mm NATO ammunition.

The M28 used 7.62x51mm NATO ammunition, which was a commonly used round in assault rifles, carbines and light machine guns. Lighter than most UNSC calibres, it was nonetheless perfectly suited to selective fire infantry rifles such as the M28; the round offered controllable recoil together with good range, accuracy and adequate stopping power. The round achieved less range and power than other infantry cartridges, notably the 9.5x60mm battle rifle round, due to its smaller size and decreased kinetic energy; however, this allowed for higher rates of fire and more controllable weapons, balancing its capabilities out and affording it good suitability for assault rifle type weapons.

The weapon, like nearly all UNSC weapons, utilised caseless ammunition, which had several advantages over traditional cased ammunition. This was a major change from Great War-era weapons, which utilised rounds which contained propellant inside metal casings. From the conclusion of the Human-Covenant War onwards, the UNSC worked on increasing the lethality of its infantry firearms; aside from the development of directed energy weapons, one element the UNSC looked at was the application of caseless ammunition. This was already used with operational success in the M7/Caseless Submachine Gun, though was limited to this weapon and not available in other calibres. Developments in technology, however, allowed the widespread adoption of caseless ammunition from around two decades after the war onwards, with newer replacement weapons discarding more traditional ammunition.

Unlike experimental caseless munitions of the late 20th century, the M28's ammunition maintained a tolerance similar to traditional, cased bullets. This was achieved by the propellant being coated in a thin layer of water, heat and dirt resistant coating. This also allowed rounds to be handled and manually loaded, as well as improving their 'drop resistance' or shock tolerance significantly. This also increased its shelf life considerably. These qualities were present in the M7/C Submachine Gun's ammunition, and carried over to the UNSC's next generation of caseless weapons.

Caseless ammunition offered several advantages. The most noticeable was an increase in muzzle velocity; not only was more propellant available per bullet with the caseless system, the propellant released significantly more energy when combusted. This higher muzzle velocity led the M28 to deal noticeably increased damage to the target in terms of kinetic effects; this also markedly improved its armour and shield penetration characteristics. The 7.62mm round's muzzle velocity was typically two to three times higher with caseless ammunition than traditional cased types, making it significantly more effective than its more traditional predecessors and meaning even assault rifles and carbines were capable of taking on shielded and armoured Covenant infantry. It was largely this increase in lethality that convinced the UNSC to maintain ballistic weapons for the bulk of their weapons, rather than developing and adopting plasma weapons of their own.

Caseless ammunition also reduced the complexity of the M28's internal mechanisms, as there was no need for extraction and ejection of spent casings. As the overall round was smaller, it allowed for larger capacity magazines, and its significantly reduced weight increased the amount of ammunition a soldier could realistically carry.

The 7.62mm bullet was actually embedded inside the solid propellant 'block'; it, the bullet and the primer were held together by a combustible glue. When fired, everything in the chamber save the bullet fully combusted, leaving no residue in the chamber and propelling the bullet down the barrel. The propellant itself was an advanced solid, plasma-based substance similar in composition to that of the the experimental M634 HP-SAP, which gave high muzzle velocity; this in turn increased lethality on contact with the target. The block was highly resistant to temperature, which prevented it from combusting prematurely, for example on contact with heat inside the weapon, or external heat sources.

There were numerous forms of 7.62x51mm NATO ammunition available to the UNSC, each differing in usage and effects. This varied from the simple and cheap to the complex and expensive to manufacture. The most commonly issued and utilised round was the M602 S/AP-HE, or Shield/Armour Piercing-High Explosive, which was a balance of potency and cost. Specialised ammunition, such as the M601 SAP-HEI, was generally only issued to high priority units and special forces, while forms such as the M603 Jacketed Hollow Point specialised to a degree where they were limited in their effectiveness, and as a result were not commonly issued.

- M601 Semi-Armour Piercing-High Explosive Incendiary: The M601 Semi-Armour Piercing-High Explosive Incendiary, or SAP-HEI, was an ammunition type combining both an armour piercing and an explosive/incendiary capability. The bullet's tip was filled with a highly incendiary chemical, which burned at several thousand degrees upon impact with a target, damaging or melting armour and heavily affecting shields. Behind this was a high explosive component which detonated immediately on impact with a target, further damaging the area. Behind this was a solid core penetrator of depleted uranium, held in a backing 'cup' of steel. The components were held together in a copper or lead jacket. Upon hitting a target, the incendiary and explosive properties would damage the target area, aiding considerably in the depleted uranium's penetration into the interior. The penetrator featured a self-sharpening tip and was itself pyrophoric, meaning that it ignited upon impact with the incendiary material. It then punched through any remaining armour, having been ignited at this point and also carrying with it any remaining incendiary material from the tip. Effects on the target, especially if it was organically-based, were catastrophically damaging; the round would typically bypass any present armour (following rapid depletion of shields) and propel an incendiary penetrator and secondary incendiary material into the target's innards. However, the round's complexity in design made it expensive and its use was usually reserved for special forces and select few line units.

- M602 Shield/Armour Piercing-High Explosive: The M602 Shield/Armour Piercing-High Explosive, also known as S/AP-HE, was the most common and effective type of ammunition employed in the 7.62x51mm calibre. The bullet itself was coated in a polymer which acquired an electric charge while in flight, aiding the bullet's kinetic energy in depleting shielding and, although it had little effect on armour, increased the bullet's drain on shielding by roughly half. The further the bullet travelled in the air, the greater the charge it acquired, so this effect was at its most potent at longer ranges and nearly negligible at extreme close range. The tip of the round consisted of a deforming ballistic cap; a lightweight element which crumpled upon impact with a target and gave the bullet superior aerodynamic characteristics. The bullet's armour-piercing core was a 'CVT' (Chromium Vanadium Tungsten) and Austenitic Steel alloy with a self-sharpening tip; when it fractured upon impact, it would do so in a way that the remaining element was still a sharp point. Behind this was a pre-fragmented block of 'TC3' alloy, composed of tungsten, cerium and copper carbide, with a delayed action fuze in the centre. This alloy maintained similar incendiary and pyrophoric properties to uranium, though without associated radiological effects. A millisecond after the bullet's penetration of the target, the fuze would activate; this fuze contained a plasma-based high explosive compound, which explosively fragmented the pre-weakened TC3, in turn heavily damaging organic structures and internal organs. As a secondary function the TC3 was incendiary, causing severe secondary damage to soft targets.

- M603 Jacketed Hollow Point: M603 Jacketed Hollow Point (JHP) round was a specialised munition for unarmoured and lightly armoured infantry, being at its most effective when utilised against Kig-Yar and Unggoy.

- M604 Tracer: The M604 Tracer

- M605 Armour Piercing High Explosive: The M605 Armour Piercing High Explosive round (AP-HE) was an effective armour defeating round, used as a cheaper alternative to more expensive semi-armour piercing high explosive incendiary (SAPHEI) ammunition. The bullet's tip was composed of a hollow, lightweight ballistic cap which deformed on impact, and improved the bullet's ballistic properties. Behind this was an armour piercing penetrator composed of CVT (Chromium Vanadium Tungsten) and Austenitic steel alloy, with a self sharpening tip. The remaining length of the bullet was comprised of 'stressed' steel; the interior of this steel was hollowed out and contained explosive filler and a delayed action fuze. Shortly after impact this would detonate, fragmenting the steel and causing effects similar to a miniature fragmentation grenade, albeit designed to detonate inside an organic body.

- M606 High Explosive Squash Head: The M606 High Explosive Squash Head round, or HESH, was designed to deal damage to a target without needing to defeat its armour, thus making it ideal for shielded and armoured targets. The bullet was formed of a thin steel shell filled with plastic explosive, with a delayed action base fuze towards the rear. Upon impact with a target the bullet would deform and form a disc or 'pat' of explosive with an increased surface area. A millisecond later the base fuze detonated, creating a shock wave that, owing to its large surface area and direct contact with the target, was transmitted through the material. The round was able to effectively defeat active shields due to primary kinetic, secondary explosive and tertiary kinetic effects. If impacting on armour, the round would cause little damage to the armour itself but directly damage the target through the resulting shockwave. This shockwave was highly disruptive to internal organs, often tearing vital organs from their connective vessels or reducing them to a thick paste. In some cases, the shockwave would cause a secondary effect known as spalling, where minute fragments of the armour's internal layer would be projected off it at high velocity, known as spall. In these cases secondary damage was enhanced by a sort of fragmentation effect inside the target's own body, and caused by their own armour. The round was relatively cheap to produce and was effective against unarmoured, armoured, unshielded or shielded infantry targets.

Gallery[]

| |||||||||||||||||||||||